packCUT / 15 kW

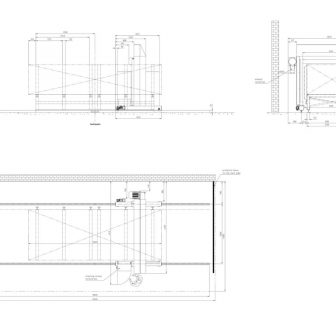

movable saw unit with feed on rails of any length

- enables cutting larger packages

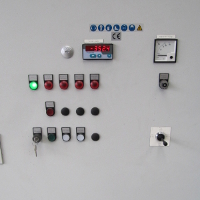

- each time adapted to the customer’s needs thanks to various additional options

The saw configuration is very flexible and allows for special requirements regarding the width and height of processed packages.

The saw moves along the rails to the desired cutting position, thanks to which the installation can be easily extended at any time.

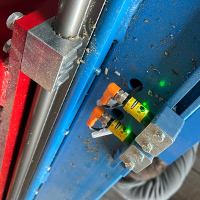

Digital indication of the length of the cut package or pneumatic holding down appliance of the pack are some of the additional options that can be included in the packCUT line.

Download

Ask about individual offer

Find missing or used spare parts

Why choose PRINZ chainsaws for wood cutting?

Presentation and training

We conduct professional operating training of delivered equipment. We share our knowledge gained over the years, so you can maximize the efectiveness of your work.

Fast execution of order and installation

We do our best to execute all orders and installations professionally and comprehensively, but most of all – fast and efficiently.

Service

We provide warranty and post-warranty service, as well as quick delivery of spare parts from warehouse in Poznan, PL.