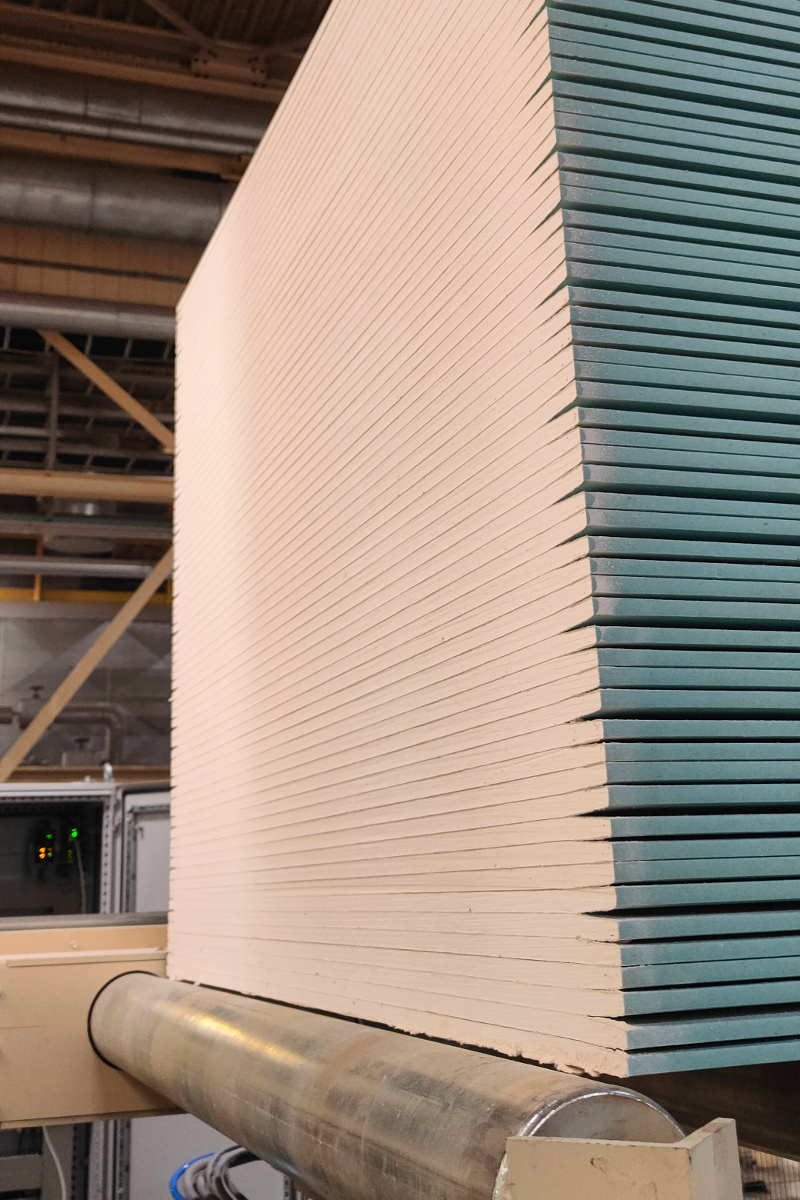

Gypsum plasterboard is a popular material in the construction industry. Production is increasing worldwide from year to year. However, cutting plasterboard is a particularly big challenge for manufacturers, especially when the gypsum plasterboards are to be cut in a package.

The material is relatively soft and brittle, which can lead to damage edges and breakage if not cut properly. In addition, dust and dirt can be a major concern when working with plasterboards.

The high abrasiveness of the material is also an extreme challenge for tools and machines. In order to meet the challenges of cutting plasterboards and achieve a high-quality result, PRINZ started developing compact and efficient solutions as early as 1990.

The constant further developments, in close cooperation with many manufacturers of plasterboards, have made PRINZ the world’s leading supplier of tools and gypsum saws for cutting packages of gypsum boards.

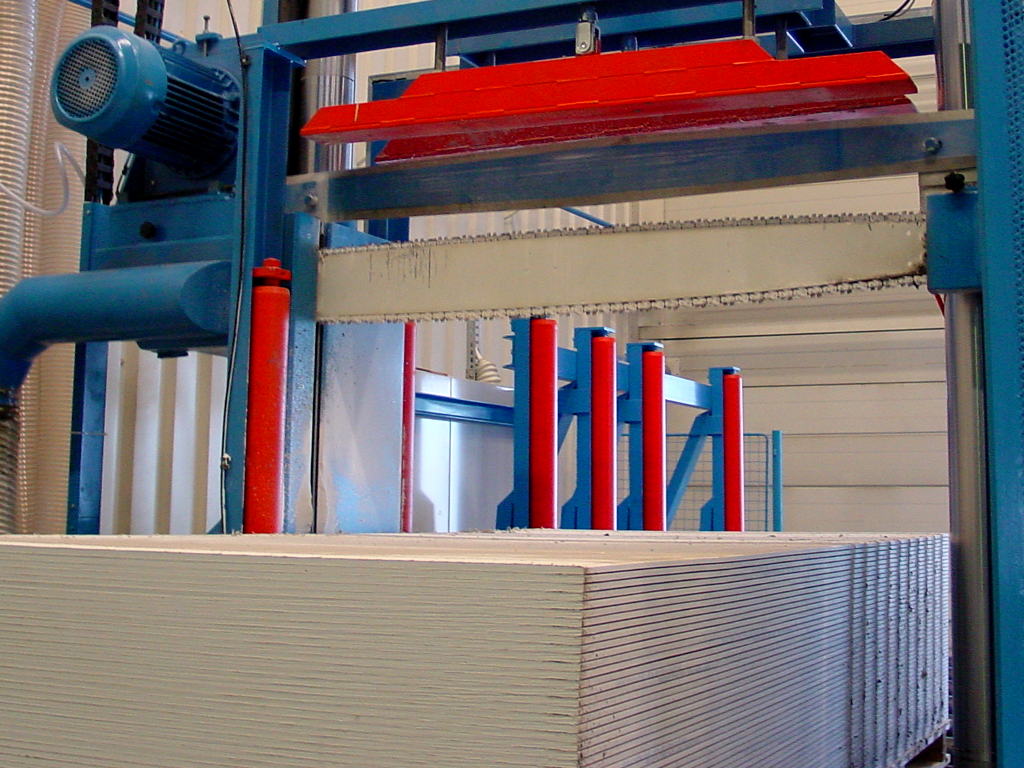

The PRINZ PC120 has been developed specifically for very high production output and a fully automatic, uninterrupted production process. Thanks to the PLC control system, the automatic cutting sequence parameters can be changed easily, with precision cutting guidance on both sides ensuring maximum cutting accuracy, even at maximum cutting output.

Saws for plasterboard cutting

Plasterboards are widely used in the construction industry and their popularity is constantly growing all over the world. They are an irreplaceable building material for interior finishing, creating partition walls or suspended ceilings. In order to use them, it is necessary to properly prepare the plasterboard packages, taking into account their length. This task brings many challenges. On the one hand, this material is soft and brittle, which makes it easy to damage during cutting, and at the same time highly abrasive, reducing the life of the cutting unit parts of the saw used for cutting. In addition, dust and dirt generated during processing require the use of appropriate dust extraction systems. Therefore, it is necessary to select the right station for cutting plasterboard.

Problems related to cutting plasterboard

The main problems faced by saw operators cutting plasterboard are:

- Edge damage: Improper cutting of plasterboard leads to fractures and uneven edges, which affects the aesthetics and functionality of the structure and increases the amount of work during assembly.

- Material abrasiveness: The high abrasiveness of plasterboard requires the use of specialist tools that ensure precise and clean cutting of the plasterboard, minimizing material loss. The durability of the saw chains and guide bars used for cutting becomes very important.

PRINZ solutions

PRINZ offers advanced saws for cutting plasterboard packages, which perfectly cope with the challenges posed by this material. Our saws are designed with maximum precision and efficiency in mind, and the flagship model PRINZ PC120 enables fully automatic and uninterrupted performance of plasterboard cutting processes. This guarantees optimisation of working time and minimization of waste.

Advantages of PRINZ tools

The saws we create for cutting plasterboard packages are devices with many advantages. The most important of them are:

- High efficiency: PRINZ tools are designed with high efficiency and accuracy in mind, enabling fast and efficient cutting of plasterboard.

- Cutting precision: Accurate, double-sided guidance of the cutting unit ensures high quality of finish, eliminating the risk of unevenness and damage to the edges.

Application in various industries

Plasterboards are mainly used in construction. They are used in various construction applications, from interior finishing to partition wall construction or various decorative forms. Industrial production of plasterboards requires reliable machines and cutting tools that will ensure the consistency and quality of each delivered batch of boards.

Why it is worth choosing PRINZ tools

Many satisfied customers speak in our favour. PRINZ cooperates with many plasterboard manufacturers worldwide, supplying reliable tools for cutting plasterboard. Our many years of experience are also our advantage. Since 1990, PRINZ has been producing and developing tools for cutting plasterboard packages, gaining the trust of customers thanks to innovative solutions and high-quality products.

PRINZ offer

PRINZ products are compact, efficient and easy to use. They are an excellent choice for both medium and large companies. You can count on our full technical support. We provide expert advice to enable optimal use of PRINZ tools.

We invite you to take advantage of our offer and join the group of satisfied customers who have appreciated the quality and reliability of PRINZ tools for cutting plasterboard packages.