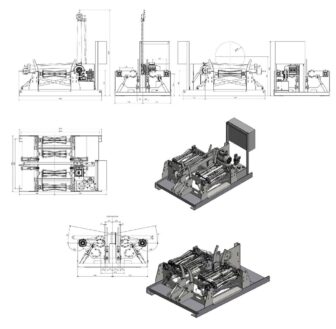

LOGSTAR combi / 15kW

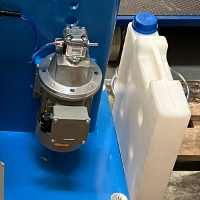

station with hydraulic feed of cutting unit, clamping device, and raised/lowered internal rolls of the bevel gear roller table

- massive construction will cope with even the most difficult conditions

- perfect for building into an automated line

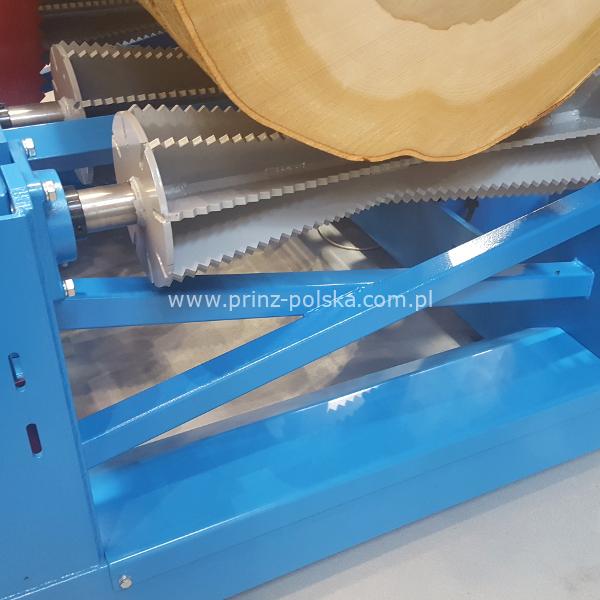

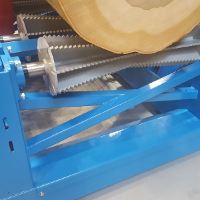

Electrically powered, hydraulic machine for cutting logs, with a feeding bevel gear roller table, which feeds logs (2 rolls) and outfeeds cut beams (2 rolls), hydraulic clamping device which holds down logs during cutting, hydraulically raised/lowered internal rolls of the bevel gear roller table.

Perfect for building into an automated line. Modular system of our offer allows to adjust specific and individual customer requirements.

Massive construction will cope with even the most difficult conditions. High efficiency of the machine is also guaranteed during cutting logs of a larger diameter (standard up to ø100cm).

Download

Ask about individual offer

Find missing or used spare parts

Why choose PRINZ chainsaws for wood cutting?

Presentation and training

We conduct professional operating training of delivered equipment. We share our knowledge gained over the years, so you can maximize the efectiveness of your work.

Fast execution of order and installation

We do our best to execute all orders and installations professionally and comprehensively, but most of all – fast and efficiently.

Service

We provide warranty and post-warranty service, as well as quick delivery of spare parts from warehouse in Poznan, PL.