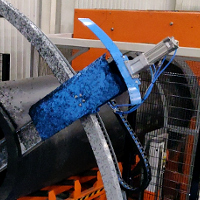

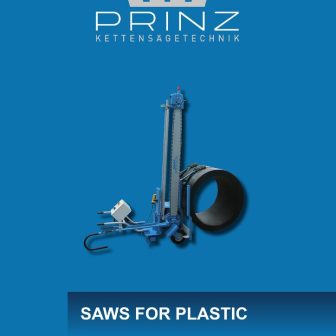

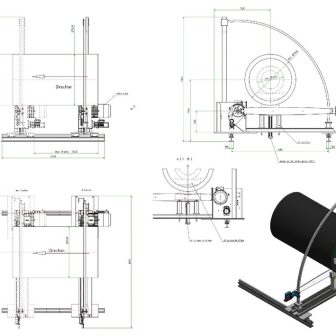

uniBLOCK PE / 11 kW

industrial plastic pipes cutting station, during extrusion

- massive guide bow for precise cutting, accuracy: +/- 2 mm

- 11 kW motor, possibility of cutting plastic pipes with a maximum diameter of 2500 mm

Download

Ask about individual offer

Find missing or used spare parts

Why choose PRINZ chainsaws for cutting of plastic?

Consulting

We conduct professional training in the use of the delivered equipment. We share the knowledge gained over the years so that you can maximize the effectiveness of your work.

Fast implementation

We try to carry out all orders and installations professionally and comprehensively, but most of all – quickly and efficiently.

Service

We offer warranty and post-warranty service as well as quick delivery of spare parts from our warehouse in Poznań.