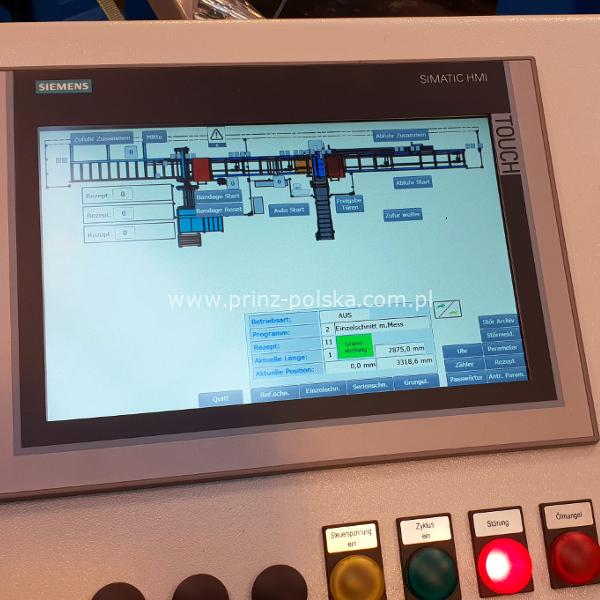

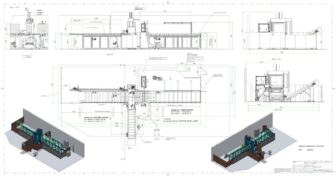

PC120 / 15 kW

stationary saw unit with package feed on roller conveyor

- highest cutting accuracy +/- 1 mm and efficiency of cutting

- the line is customized to individual client’s needs every time thanks to various options

Automatic line PC120 for cutting lumber packages and boards, equipped with a roller conveyor which transports and removes the cut material. Centrally located saw unit. The line is customized to individual client’s needs.

Ideal for combining with other components, e.g. package strapping device, packing device or shock table which levels package on one side. Highest accuracy +/- 1 mm and efficiency of cutting.

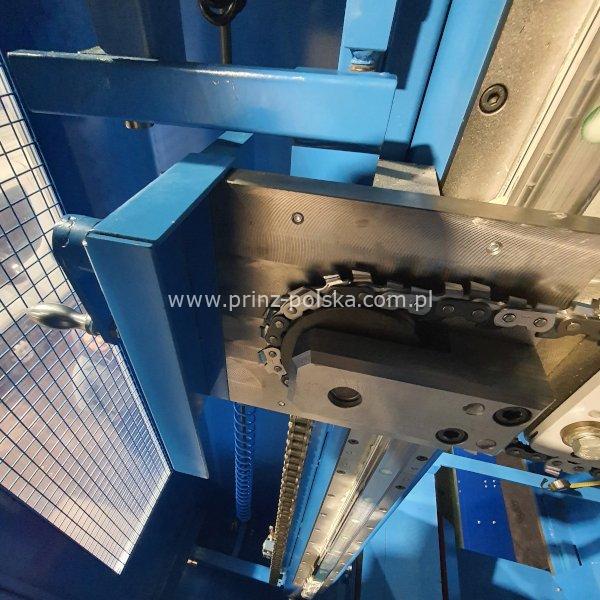

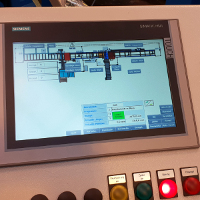

The patented DOUBLE ACTION system enabling alternate cutting of the package from top to bottom and bottom to top without the guide bar returning and the possibility of using cross-chain buffers make it the most efficient and comprehensive line in our offer.

The patented PRINZ DOUBLE ACTION TECHNOLOGY

Download

Ask about individual offer

Find missing or used spare parts

Why choose PRINZ chainsaws for wood cutting?

Presentation and training

We conduct professional operating training of delivered equipment. We share our knowledge gained over the years, so you can maximize the efectiveness of your work.

Fast execution of order and installation

We do our best to execute all orders and installations professionally and comprehensively, but most of all – fast and efficiently.

Service

We provide warranty and post-warranty service, as well as quick delivery of spare parts from warehouse in Poznan, PL.