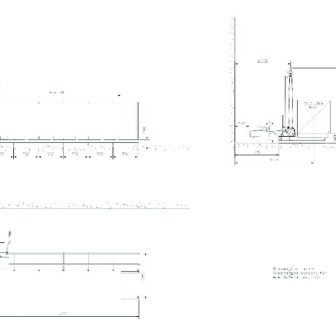

TWIN-L / 7,5 kW

station with manual feed of cutting unit and saw on the frame

- increased cutting accuracy thanks to the package positioning frame

- always perpendicular positioning of cutting unit in relation to the package

Enables usage of PROFICUT light / strong in stationary version, thereby increasing cutting accuracy and efficiency. Saw can be easily mounted on frame. Manual left / right saw feed.

Before start, the saw is blocked and secured against movement. Packages, which are placed on the table, are pushed towards vertical profiles and positioned precisely – perpendicular to the cutting unit. The construction can be mounted on elevated foundations, which makes it possible to remove and collect waste.

Download

Ask about individual offer

Find missing or used spare parts

Why choose PRINZ chainsaws for wood cutting?

Presentation and training

We conduct professional operating training of delivered equipment. We share our knowledge gained over the years, so you can maximize the efectiveness of your work.

Fast execution of order and installation

We do our best to execute all orders and installations professionally and comprehensively, but most of all – fast and efficiently.

Service

We provide warranty and post-warranty service, as well as quick delivery of spare parts from warehouse in Poznan, PL.